Water quality and purification technology

To limit corrosion and limescale deposits in the electrolyzers, high demands are placed on water quality.

Please contact us.

How do we make water for hydrogen production?

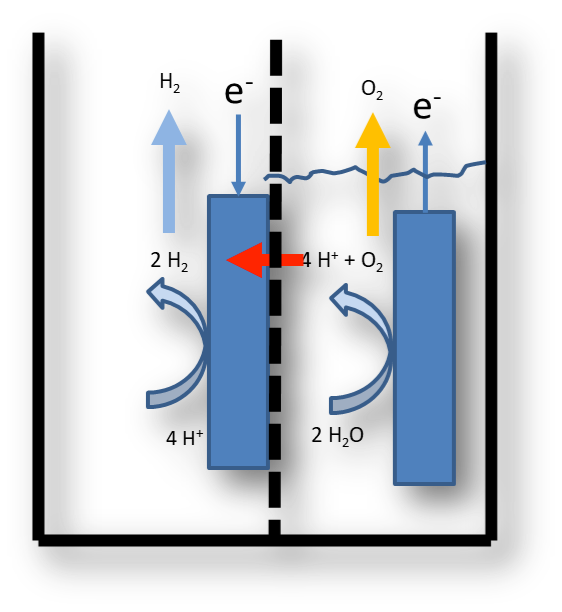

There are various electrolysis techniques to produce green hydrogen, with AEM (anion exchange membrane) and PEM (proton exchange membrane) techniques currently being considered the most efficient techniques with the highest production yield. However, the efficiency is partly determined by the quality of the feed water for the electrolyzer. Salts and organic components that occur naturally in ground or surface water can cause corrosion and limescale deposits, which can contaminate the electrodes and produce less hydrogen.

PEM-elecrolyze

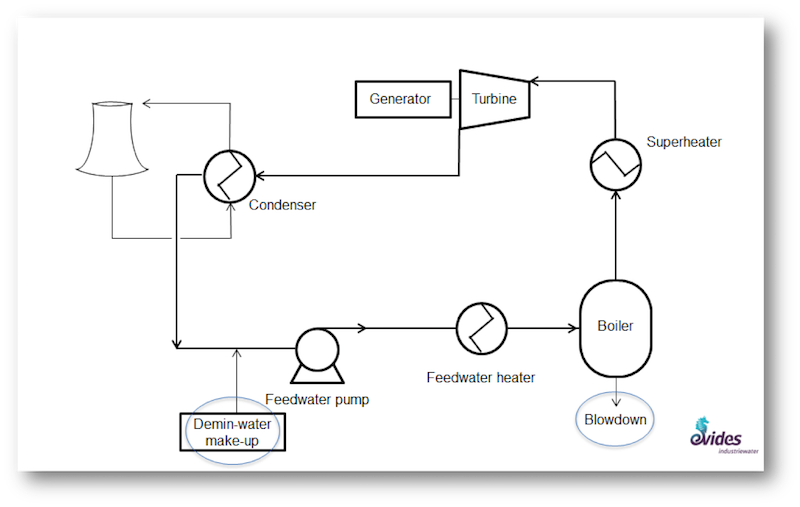

A similar consideration applies to water quality in the production of gray and blue hydrogen. Corrosion and limescale deposits are disastrous for the lifespan of the turbine used to convert methane into hydrogen with steam. Furthermore, lower water quality results in higher water consumption due to a higher flushing and waste water volume with associated costs.

Steam turbine flowchart

Corrosion and scale formation on turbine blade

Water quality requirements

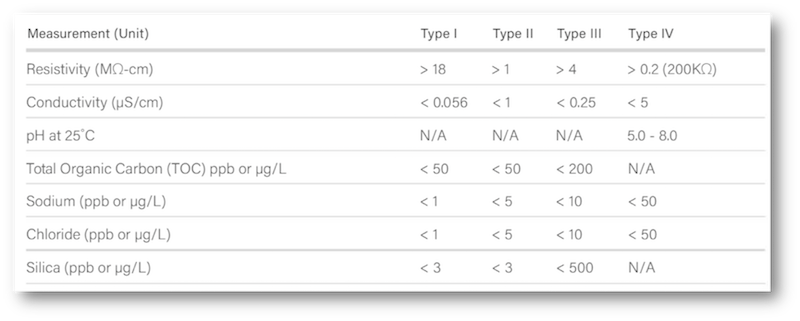

The demands placed on water quality during hydrogen production are therefore high and approach the gradation for so-called “ultra-pure water” with a conductivity of <0.1 µS/cm and preferably even <0.06 µS/cm. Furthermore, there are also specific requirements regarding all loose ions such as silica (< 5 ppb), sodium and chloride content (< 10 ppb). The suppliers of electrolyzers often refer to the water quality as stated by the ASTM in accordance with the following table.

Source: ASTM Standards for pure water (ASTM D1193-91)

Exact specifications for water quality differ per project and often depend on the chosen hydrogen production method and the manufacturer of the equipment required for this. Customization is required for these applications to meet the specifications for the project in question. Because Evides is independent in the choice of water purification technology, customization can actually be delivered per project, and in consultation with the customers. Evides also provides financing, operations and maintenance of the water treatment plant.