How much water is needed for hydrogen production

Hydrogen production requires different types of water in different quantities.

Please contact us.

How much water is used for hydrogen production?

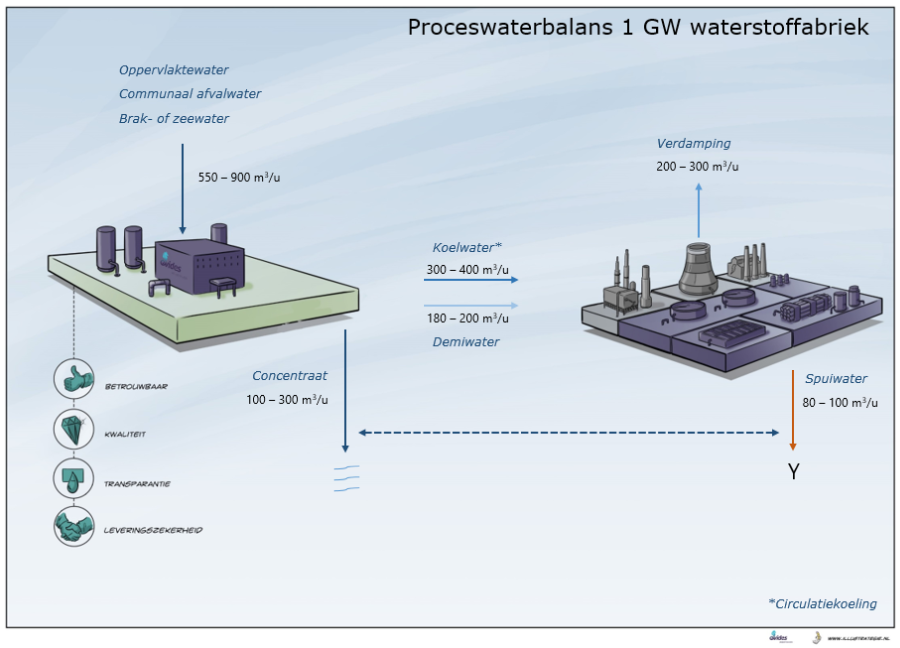

The figure below shows an overview of a hydrogen factory where water is required for the following applications:

- Raw feed water for the water treatment plant (no. 3)

- Demineralized water for the electrolyzers (no. 8)

- Cooling water for cooling the electrolyzers and compressors (no. 13)

- Facility water for sanitary, firefighting and maintenance

Source: Creative Commons Attribution – No Derivatives License (CC BY-ND 4.0)

Water for hydrogen

A hydrogen factory with a production capacity of 100 MW requires approximately 18 to 20 m3/h of demineralized water. However, the feed water consumption of a demineralized water treatment plant is higher because the purification process produces a residual flow of approximately 20% containing organic substances and salts. When using wastewater or seawater as a source, this residual flow can increase to 60%. A hydrogen factory with a production capacity of 1 GW will then consume 230 to 500 m3/h of feed water for demineralized water production, depending on the water quality of the source.

Cooling water

The electrolyzers and compressors for hydrogen production are cooled because in these processes approximately 25% of the power is converted into heat. At smaller hydrogen plants with a capacity of 10 to 50 MW, air cooling is often chosen as the most attractive economic option.

However, when scaling up a hydrogen plant to, for example, 1 GW, water cooling is a cheaper alternative. In general, two options are considered for this in the form of a once-through or circulation cooling system.

With flow cooling, river or sea water is taken in and discharged after the heat exchange. This method has no impact on the availability of the water system, but does lead to an increase in the temperature of the discharged water. The water flow rate, 40,000 to 50,000 m3/h for a 1 GW hydrogen plant, and energy consumption is significantly higher than with circulation cooling.

With circulation cooling, the water is recirculated and partly drained. The water consumption for circulation cooling at a 1 GW hydrogen factory is between 300 and 400 m3/h, depending on the cooling water quality and the possibility of disconnecting heat via a heating network.

Wastewater

The wastewater released during hydrogen production consists of the following flows:

- Concentrate from the water treatment plant

- Blowdown water from the cooling towers

- Facility water

The water released from the gas separators during hydrogen production (see figure 1) is returned to the electrolyzers.

The concentrate flow from the water treatment plant can usually be discharged directly into the surface water. However, the discharge water from cooling towers is conditioned with environmentally harmful chemicals such as biocides and corrosion inhibitors and is therefore not suitable for direct discharge to surface water. The use of harmful cooling water chemicals is also increasingly restricted by legislation, making 'green chemistry' and low-chemical cooling increasingly attractive.